On my previous post: http://relaodthis.blogspot.com/2012/10/reload-1.html

I concluded with an overview of Re-Loading specific equipment costs. There are many options that can you started for well under $500, but, its more addictive than Chocolate !

See comments on this post: http://relaodthis.blogspot.com/2012/10/just-another-hobby_21.html

NOTE: For “How-To” instructions Youtube is a great source. These two channels have first rate uploads:

OBXSOLWIND .. Link to example: http://www.youtube.com/watch?v=ET9kwN7tcpI&list=UUsyN0uWZnXJpN00gIW4fQlw&index=15&feature=plcp

One additional good quality link from; SoCalPreppers http://www.youtube.com/watch?v=IN9ScN0TaOI&feature=plcp

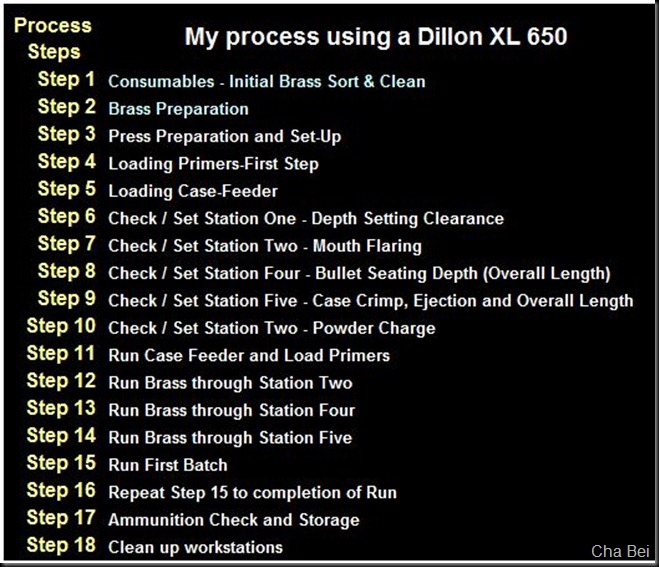

I’m providing a set of; written and illustrated in-sequence process steps, with a few pointers and tips along the way.

Overview:

Step one: Acquire all the consumables required:

Brass Shell Casings; Buy New, Use Once-Fired (from factory ammo) or collect at the shooting range.Brass: Sort – Inspect – Clean – Re-Inspect – Store for use.

Primers & Powder, I buy these.

Bullets: Buy, and or Cast. I have no plans to cast.

Range / Mixed Brass: Sort through and segregate by size. A sub-sorting by manufacturer can be done. I stopped doing this, as recreational pistol shooting does not require this type of consistency. During the sorting a first Visual inspection is performed, suspect cases are rejected.

Once sorted and or visually inspected the Brass is cleaned. I use Dry Media in a Vibratory Case Cleaner. ALL brass, even new never fired. Separate the brass from the cleaning media. I use the Dillon CM-500 Separator

http://www.saami.org/

http://www.saami.org/A SAAMI spec. Case Gauge is used to inspect and sort Cases for Diameter (fit in gauge) and Case Length.

Brass that has been sorted (left) and a small batch of Cleaned Brass (right)

Store in your container of choice.

Store in your container of choice.Step Two: Case Preparation .. to be continued.

No comments:

Post a Comment