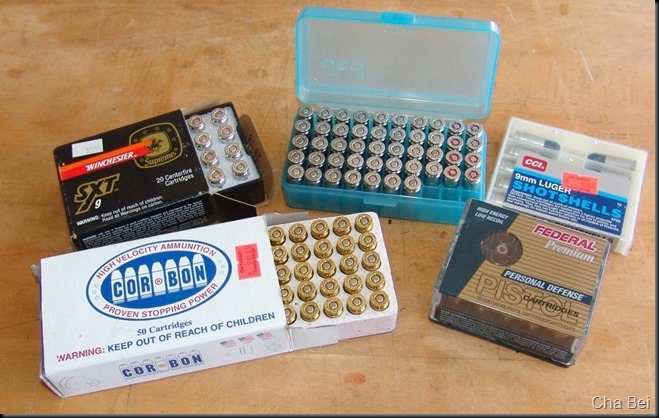

Designated as the: 9×19mm Parabellum or 9x19mm, 9x19mm NATO or 9mm Luger, is probably the most popular center fire round to both shoot and reload. .. SAAMI Spec Sheet:

Loading NEW, never fired, brass cases poses little or no problems to the knowledgeable Re-loader.

It is when you reload Mixed Brass fired at least once, more likely; fired and reloaded many times, that the “Finicky” nature of the 9mm raises concerns.

I’m in the process of reloading 6,000 rounds of Mixed Range Brass, as sold by Dillon Precision .  This probably offers most of the variations and problems that one can encounter. Mixed sizes, various chamber expansion dimensions (AKA Glocked-Up-Base Bulge), deformation and or cracks/dings, Steel cases etc. All in all there was approximately 3% cases rejected during case clean/prep.

This probably offers most of the variations and problems that one can encounter. Mixed sizes, various chamber expansion dimensions (AKA Glocked-Up-Base Bulge), deformation and or cracks/dings, Steel cases etc. All in all there was approximately 3% cases rejected during case clean/prep.

Brass processing is ALL important; Cleaning, Inspection, Preparation and Conditioning.

Cleaning: Establish a lot/batch size that your cleaning system can handle. Visual inspection of each batch, looking for any obvious non-compliances. A 2nd. quick visual after cleaning. Store the cleaned and visually inspected brass.

Visual Inspection: With 9mm this tends to be a tedious process, but one that I perform on all brass. Weed out any non-conformances and mixed cases that can be spotted.

Now we start to Prep and Condition the brass for reloading. Based on my set-up this is what works for me. Using the Evolution Gun Works undersize die and Dillon XL650 makes this step less arduous than Single Stage or Turret press set-ups.

Set up a spare Tool Head in the XL 650.

Set the Standard Dillon Carbide 9mm Size and De-cap die in Station #1

And with the EGW Undersize Die in Station #3, with the De-Priming Pin REMOVED

And a 38 Special; Size and De-prime in station #4, With the De-Priming Pin REMOVED this completes the equipment required to Prep and Condition the; Many fired and mixed 9mm range brass.

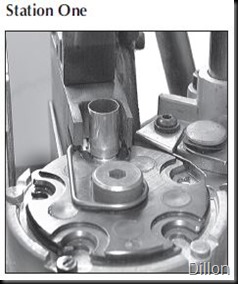

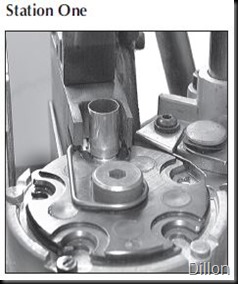

Station #1: Set the Size and De-cap die as normal, light contact with the Shellplate.

Stations #2, and #5 are empty

Station #3: Set the EGW die with light contact on the Shellplate

Station #4: This one is different .. The 38 Special is a Straight Wall Case (vs the slight taper 0.011” of the 9mm) use this die to RE-SIZE only the first 0.200”. This provides a good dimension to ensure a slight interference fit with the 9mm Bullet. Seen here installed on my Turret press:

Run all the brass through this Progressive Three Die set-up .. 1) standard Size and De-prime, 2) Undersize the Outer Diameter ( to accommodate the Glock type chambers), 3) Slight squeeze on Bullet Seating Section of the case. Again weed out any brass that is non conforming. NOTE: on the XL 650 Station One Loading Finger (item 2) is an exact match for 9x19 cases .. 380 auto and 9x18 can be spotted.

This yields a reliable Re-Sized Case from a Hodgepodge of Range Brass. Now its time to proceed and finish the Case Prep then Reload 9mm ammo.

Some of the process generated detritus destined to be recycled, Spent Primers and Brass Cases:

Finishing case prep and final visual inspection. First step is to measure Case Length. Select a significant sample size from the 5,600+ cases. Check these to the SAAMI standard: 0.754” to 0.749”. Results of this inspection shall determine whether to Trim Case Overall Length or not. After length check Primer Pocket Sizing and Cleaning is a MUST.

XL650: Install 9mm Tool Head, Shellplate and Small Primer Feed Disk Assembly. As the brass has been “Pre-Processed” Station #1 should be minimal effort and provide a “Double Confirm” of Size and De-Prime.

Station #2 .. Install Primer-Forward Stroke .. Down Stroke: Mouth Flare / Bell-Mouth case. Set this to a minimum – just enough to allow the bullet to center locate and discharge the powder load.

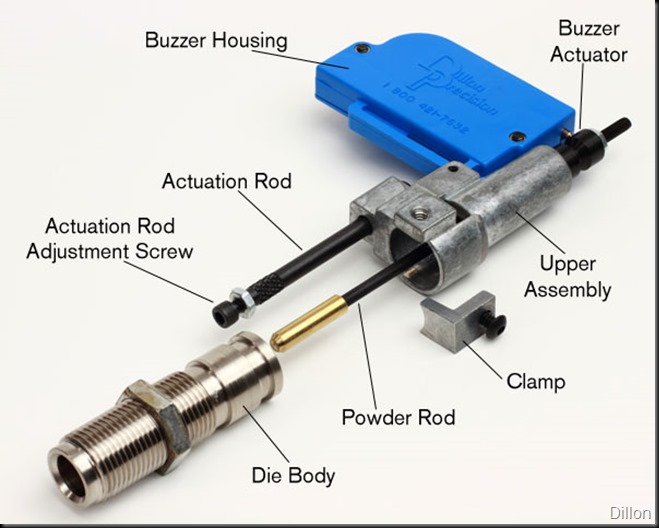

Station #3 .. Powder Check .. Over / Under or Correct loading is detected via Audio alarm.

Station #4 .. Bullet Seating … Depending on the Bullet type: Round Nose – Flat Point etc set the Overall Length and use Case Gauge to verify compliance.

Station #5 .. Bullet Crimp .. This is another area where the 9mm can be finicky, so pay attention. I only use Copper Plated Bullets and check each batch for OD consistency. A small variation can be tolerated, this NOT for Bench Rest shooting.

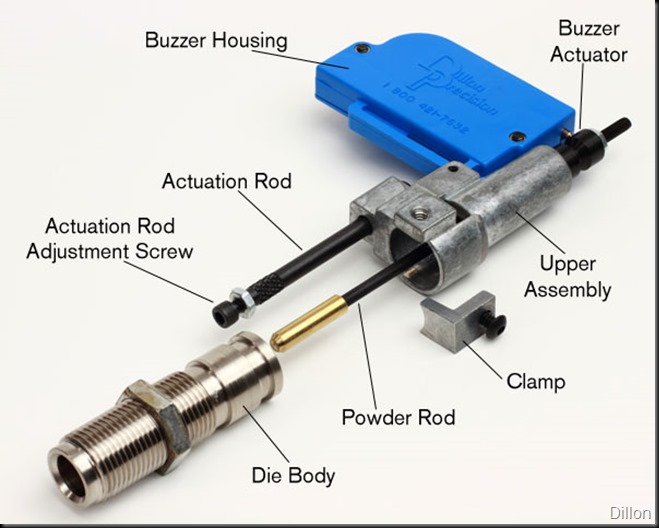

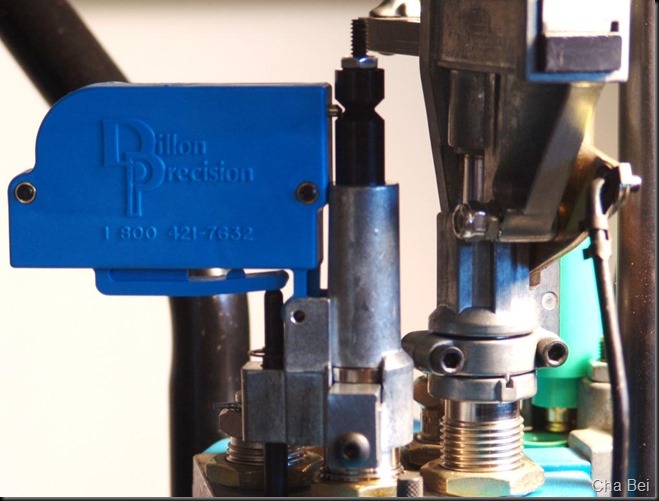

Station #3 on the XL 650 provides a location to install a Dillon custom powder check system. Very easy to install and adjust. Most importantly it works well and is dependable.

Station #3 on the XL 650 provides a location to install a Dillon custom powder check system. Very easy to install and adjust. Most importantly it works well and is dependable.  At the top of the Upstroke a charged shell casing has activated the powder check system. The grove in the sensor rod disallows closure of the sensor circuit and NO Buzzer sound .. all is well.

At the top of the Upstroke a charged shell casing has activated the powder check system. The grove in the sensor rod disallows closure of the sensor circuit and NO Buzzer sound .. all is well.

Now its on to reload some 5,900 re-sized cases. Running this in batches of 500 fits my modus operandi. The weather is awesome right now too nice to spend all day reloading.

Now its on to reload some 5,900 re-sized cases. Running this in batches of 500 fits my modus operandi. The weather is awesome right now too nice to spend all day reloading.