A good size box for a Group Therapy session Refitted with: "Phil Miracle Foam"

Refitted with: "Phil Miracle Foam"

Tuesday, 31 December 2024

45 ACP .. A well made cigar box with upgraded Hinges....

Saturday, 28 December 2024

9mm Luger: .. Plain Jane Cigar Box .. with upgrades .. complete.

A Plane Jane; but well made box: overall size 9" x 6.750"

Friday, 27 December 2024

38 Special ... very SPECIAL

Friday, 20 December 2024

Wednesday, 18 December 2024

5 new 22LR Competition Ammo Boxes (UPDATE>>>>)

Colour Samples on FOAM BLOCK ... Left to Right: Cherry Stain, Dark Walnut Stain and No Stain.

Saturday, 14 December 2024

New Boxes: 9mm.

Friday, 13 December 2024

Friday PM Wrap-Up

44 Blocks all processed through the Table saws... One saw set for 10 degree Face Cut .. Other Saw Set for Rip and Crosscut .. Also squared up the remainder of First Sheet of Foam Board .. also squared up Second Foam Board .. Set-Up Drill Press for Lower Row of 5 Holes .. Drilled one Block with all 10 Holes ...

Blocks ready for drilling Lower set of holes:

Processing New Material .. New Blocks

Using a High Density Foam Board: Very easy to Saw and Drill. No resistance, so requires diligence. Spent Wed, evening experimenting with various Saw set-ups and process sequencing.

Set to Drill at Station #1 Top Row.

Tuesday, 10 December 2024

Tuesday AM ... Wrap-Up .. Caught Up

Tuesday morning:

1) Finished up mounting Router Plate into the Table Saw Wing. This a much more stable / no flex 10mm, 0.395" thick Plate (replacing the thinner one, only 1/8", 0,125", 3.17 mm) recessed into wing.

Monday, 9 December 2024

Monday .. Very busy full day

Finished up the 22LR Box Build .. Finish continues to dry. 2 Boxes are being refinished .. All American Walnut boxes. 4 New Boxes a combination of Oak and Walnut, and 20 new 10 round Inserts, Poplar.

Sunday, 8 December 2024

Sunday .. PM overview

3 Lids in Last Glue-Up ... Block Stop in the lid used when box is closed

Sunday early AM... Drying time

Boxes 1 & 2 get a 2nd coat.. boxes 3-6 drying after first coat

Saturday, 7 December 2024

Saturday ... lot of set-ups and assembly / disassembly and applying finish..

Friday, 6 December 2024

Friday .. progress continues ....

Mounted and Set-Up the Vice on the Drill Press Table .. set to Drill a 0.0626" hole for mounting Piano style hinge for the Lid and Base...

Friday Ante Meridiem ..Update..

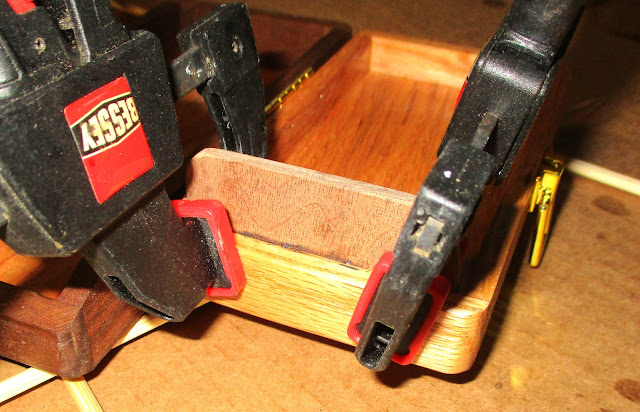

Managed to get all the Long Sides into Glue-Up yesterday .. using the parallel clamps to augment the Vices ... A base in one vice and a Lid in the other.