Monday 18 December 2023

Wednesday 19 July 2023

Saturday 3 June 2023

XL 650 .. Upgrades/Enhancements I've installed ... Numbered List

2) Spent Primer Funnel and Tube with Container.

3) Powder Measure Return Arm Retaining Bushing.

4) Station #5 Case Ejector Arm.

5) Low Primer Follower Rod Weight .. 45 ACP case.

6) Larger Live Primer Chute with Cup.

7) Primer Advance On/Off Switch.

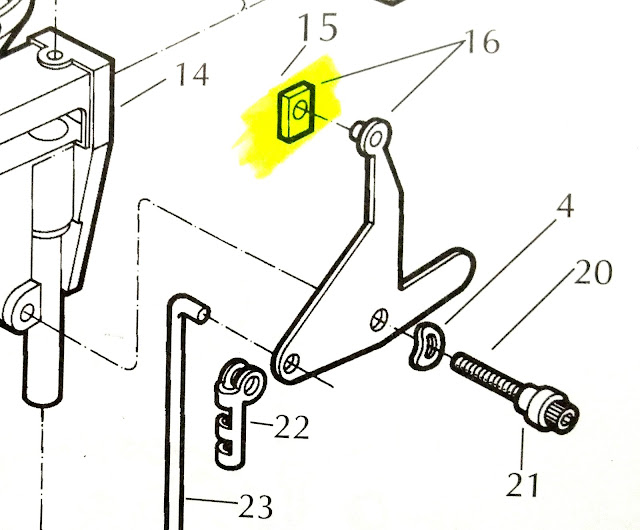

8) Shell Plate Indexing Roller Cam Arm.

9) Powder Measure Adjustment Knobs.

10) Tool Head and Shell Plate LED Lights.

11) Stations #3, #4 & #5 Locator Pin Tabs.

12) Auto Case Feed System Added Case Retention at Case Drop.

13) Press Mount to allow Larger Akro Bin Catcher.

14) Bullet Tray Mount.

15) Station #3 Powder Check System.

16) Station #1 Shell Loading Roller Bearing Cam Pin.

Thursday 16 March 2023

Wednesday 15 March 2023

Friday 10 March 2023

Friday 24 February 2023

Small differences ..No Functional impairments ..but "May" pose an unintended issue 2 of 2

Dillon Powder Bar Adjustment Bolts .. Variation on Hex head style with variation on various features that cause NO intended use issues BUT cause aftermarket Hand Knob adjusters NOT to fit securely.

Nominal Hex size- Both: 0.437" .. 7/16"

OLD Style Hex: Across the flats: 0.433" Across Points 0.495"

NEW Style Hex: Across the flats: 0.428" Across Points 0.477"

Small differences ..No Functional impairments ..but "May" pose an unintended issue 1of 2

Brass: 38 Special .. Top 3 Federal-Winchester & CBC with shallower undercut.. Bottom 3 Starline with deeper undercut. ALL 100% for intended use. Minor Difference that may or may not cause a Reloader an issue. The small undercut vary in size and may interfere with loading cases in a Dillon XL650 Station #1 Locator. USE Locator #2

Minor Difference that may or may not cause a Reloader an issue. The small undercut vary in size and may interfere with loading cases in a Dillon XL650 Station #1 Locator. USE Locator #2