A methodical approach with attention to detail is required. The Dillon XL 650, progressive press, and its peers, represent the most mechanically complex pieces of equipment you’ll find when reloading at home. I have seen some one-off, hand made, Rube Goldberg contraptions built by “Shade-Tree Re-loaders” Namely: One Eyed Jack and Three fingers Pete.

This is typical of my work station during a Press Run. No unnecessary stuff in the area. Clean and well lighted. I can tell the Low Primer indictor has sounded (rod is bottomed out) I need to recharge the primer tube, top up the powder hopper and empty the finished rounds bin .. but we are jumping ahead.

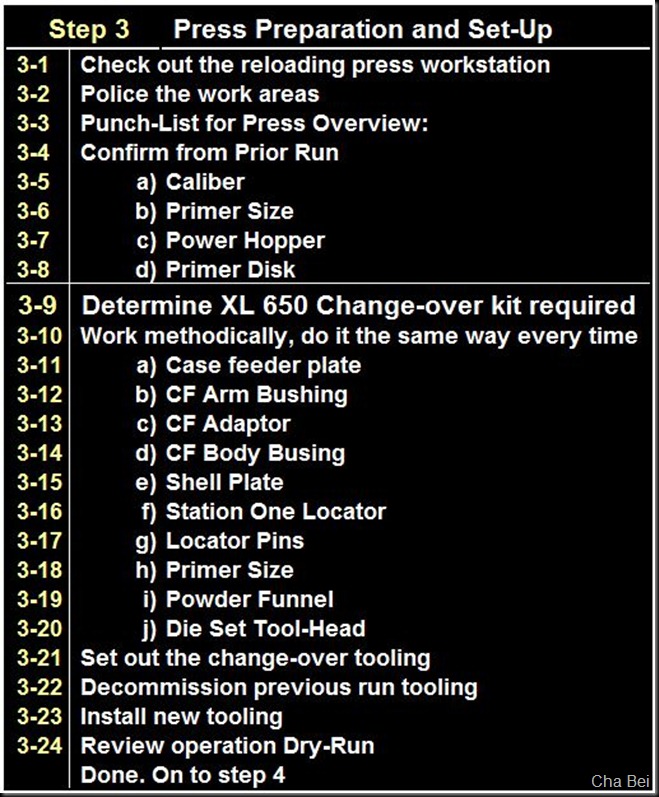

3-1 through 3-8, are primarily visual, area inspection and clean up as required. The simple punch list helps determine what has to be done to reconfigure for the next run.

Prior Session: Caliber: 357 SIG .. Small Pistol Primer .. Powder AA#5, Hopper is 1/2 full and the Small Pistol Primer Plate is installed.

3-9 From the punch list information you can establish the Change over Kit and parts required. Reference the manual, page 44 - the Caliber Conversion Chart.

3-10 through 3-21 .. Working methodically, items a) thu j) and all the required parts will be pulled together.

Changing from: 357 SIG to 9mm Luger.

3-22 .. DO NOT rush this. Removed parts do have a home, put them there. Hardware that will be Re-Used leave at the press.

First I open an empty powder canister, Remove the 357 SIG Tool-Head. Empty powder into canister and store.

Put the SIG tool-head on the stand, remove the Locator Pins and Shell Plate, put these parts in the tool stand and store.

Remove the Case Feed Bushings, Station 1 locator and store.

Done with the removal .. I’ve used this press since Aug 1996, so this is Old-Hat, but the devil is in the details

3-23 and 3-24: .. DO NOT rush this. Rebuild the press from Case Feeder down to Shell Plate.

Case Feeder, empty and ready. Change out the CF bushings (Green) and adaptor (Small)

Install the #5 Case Feed Plate and Ejector Clip. Insert the 3 station pins and Station 1 Locator.

Install Tool-Head and connect Fail-Safe rod into Powder Bar assembly

Visual check .. Index slowly .. double check .. Ok? Done!

Step 4 is next.

No comments:

Post a Comment